Application & Process :

Application & Process :

Specially designed to meet high output capacity sifting for both large capacity and small capacity process applications. Rotary Centrifugal sifter screens are ideal for suitable for wide variety of powders, granules and other free-flowing materials like soy sauce powder, wheat seedling powder, maltodextrin, flour, spices, ginger powder, curry powder, VC powder, etc. The proportion of light metal powder can be used, such as zinc oxide, magnetic materials, calcium oxide, etc.

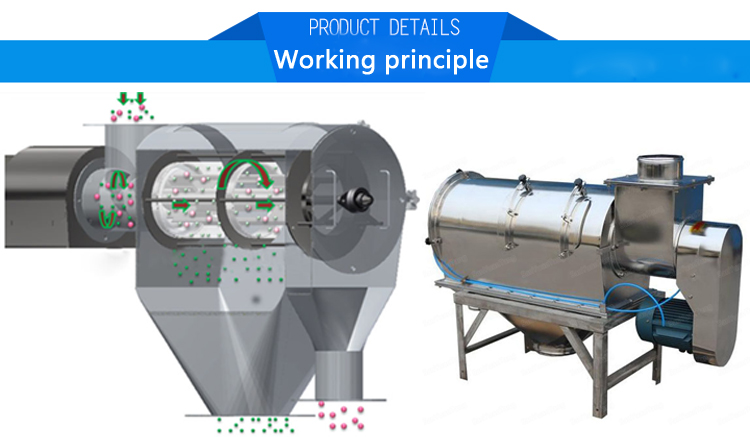

Inline rotary sifter for large capacities at small screen mesh sizes and accurate sieving. Can be used in vacuum- or pressure- conveying systems ,rotary sifter works on the principle that product entering the rotary sifter via gravity is fed into the sifting zone by means of an internal screw auger. In the sifting zone the material passes along a cylindrical screen aided by 5 rotating single row brushes or beaters, which sweep the material through the screen.

High throughput power sifter machine is the best suited for different applications where needed the high standard of hygiene and cleaning , Safety etc . It also optionally provides ease of operation and customer can be used on a variety of applications including classifying & De-dusting systems/ equipment.

This rotary sifter called Turbo Sifter gives dust free operations, Clean Hygienic & high efficient machines designed, Screen Shall be checked in 360° by loosening of a knob with easy for inspection, No contamination or leakage at the oversize end, and systems shall be Continuous discharge of oversize particles.

The equipment screen mesh is a cylinder, material, after handling by screw feeder, mixing and atomization into a screen cage, so that the material also driven by centrifugal force and cyclone by rotating the blade, forcing material injection over the screen cage, fine material discharge from fine outlet, the coarse material which can not cross the screen cage, discharged from the coarse outlet.