Ribbon blenders can be designed to operate in both batch and continuous modes. Batch type blenders can be built up to capacities of 50 m3. The ribbon blender’s versatility for blending solids combined with it ability to perform heating, cooling, coating, and other processes make it a very popular blender.

Ribbon Blender Construction and Working Application

Application of Ribbon Blender

APPLICATION

The following are the applications of the Ribbon Blender: 1) Blending large volumes of dry solids. 2) Dry powder to wet phase mixing. 3) Mixing of bulk drugs, chemicals, and cosmetic powders. 4) Dry Blending of capsule formulations. 5) Lubrication of dry granules in large quantity. 6) Heating, cooling, and drying of materials. 7) Coating solid particles with small amounts of liquids to produce formulations.

Animal Feeds

Bakery Powders

Chemicals

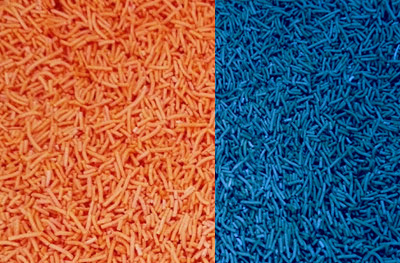

Dyes And Intermediates

Face Powders

Fertilizers

Engineered Plastics

Resin

Polymers

Pharmaceuticals

Biopharmaceuticals

Nutraceuticals

Herbal Ayurvedic Medicines

Healthcare Products

Organic Manures

Food Powders

Tea

Spices And Seasoning Powders

Oil & Ointments

Detergent Powder, Shampoo

Ointment

Seeds

Chocolates

Ice Cream

Cosmetics

Mines And Minerals

Lignite

Sigma Mixer

Chocolate and chewing gum sugar paste dual blade sigma kneader mixer machine